Why choose us?

Ronacrete highly recommend that their products are applied by an approved contractor. As a Ronacrete approved contractor we can offer a warranty up up to 15 years.

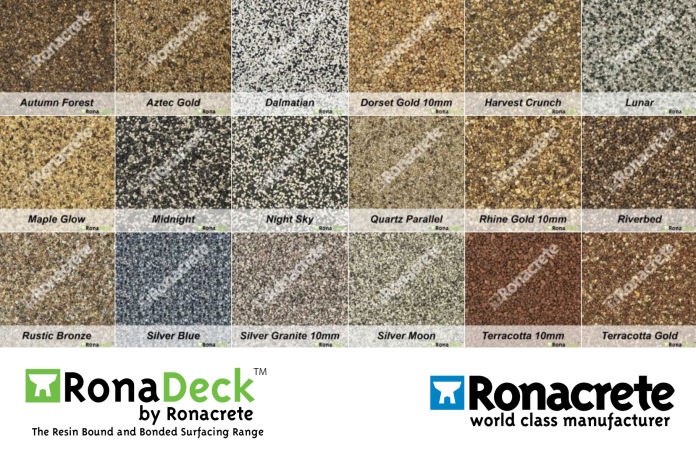

RP Construction are a specialist supplier and installer of resin bound sufaces for driveways, footpaths, walkways and patio areas. We only use the best quality Ronacrete and Ronadeck materials with a product warranty up to 15 years as an approved contractor and are able to provide a contractual guarantee for the work we carry out.

Resin Bound and Bonded Surfacing – similar names, very different materials. The similarity of the names can be a cause of confusion....

Resin Bound Surfacing is a resin bound aggregate surface for pedestrian and light vehicular traffic. Resin bound surfaces are decorative and....

We are proud to be an approved Ronadeck contractor and adhere to the high standards endorsed by Ronacrete in the installation of.....

The open matrix design of resin we use allows water to drain through to the base, eliminating water ponding and allowing water to drain to planted areas or land drains. The surfacing may be applied to SuDS compliant bases and sub-bases, reducing the impact of urban development on flood risk and allowing water to flow into water courses.

Edgings created from brick, stone, timber or steel should be installed to retain and protect the resin bound surfacing. Our resin bound surfacing we use is a two component polyurethane resin which binds a range of selected decorative kiln-dried aggregates. RonaDeck Resin Bound Surfacing provides an attractive porous surface which is strong enough for foot and light vehicle traffic.

RP Construction Resin Bound Driveways are and independent family run business part of RP Construction Ltd based in Great Baddow, Chelmsford, Essex. We have been specialising in a wide range of building work in Essex and the surrounding areas for over 20 years and pride ourselves that the vast majority of our work comes directly from recommendation.

We have become a successful and growing part of the business due to its affordable, long lasting and maintenance free resin driveway surfaces backed by a 15 year guarantee.

We have to date completed over 100 resin bound surfaces, from driveways to small borders.

We only use the best quality materials and trained staff as approved by Ronacrete.

We promise to keep you informed and up to date with the progress on your project at all times.

An an established company we have many happy customers and are willing to share this with you.

Ronacrete highly recommend that their products are applied by an approved contractor. As a Ronacrete approved contractor we can offer a warranty up up to 15 years.

Why Ronacrete?

"A resin bound surface is a problem solving paving system, with a wealth of experience in the industry we can help you with all your porous paving and retrofit paving needs. We love working with our clients to select colours, helping with costings and specification so please contact us to discuss your specific requirements any time."

Types of Resin chemical-composition :

• There are two types of polyurethane resin used for resin bound surfacing, one is UV stable (aliphatic polyurethane) which remain unchanged by exposure to ultra-violet light.

• The other, (aromatic polyurethane) will yellow and darken after exposure to UV light, thus altering the appearance of the final aggregate finish.

Aliphatic Resins

All Ronacrete products for resin bound surfacing or tree pit applications are UV stable. When retention of the original colour is required, UV stable resins should be chosen. A typical argument put forward by suppliers who do not offer UV stable resins is that many of the aggregates available are yellow and/ or brown. This assertion ignores the large number of sites where some areas are exposed and some are in permanent shade, under evergreen foliage or covered by movable objects, such as plant pots. In such circumstances, shade variation is inevitable and will become apparent relatively quickly.

There are some MDI based polyurethane binders sold as being UV resistant; evidence from independent researchers suggests that although UV “blockers” may delay the effects of UV light, blockers only delay degradation. We would suggest that designers should ask suppliers claiming UV resistance for independent evidence of long term protection from UV degradation.

Aromatic Resins

Aromatic polyurethane products are excellent for numerous uses. They are widely used for flooring, where their resistance to wear, chemical spillages and relatively high service temperatures make them an obvious choice for many industrial applications. Their lack of resistance to ultraviolet light makes aromatic polyurethanes less suitable for exterior use. Exceptions for this as undercoats protected from UV exposure. UV degradation is not limited to yellowing and darkening. Surfaces become duller and other properties such as elasticity and flexibility are also adversely affected by exposure to UV.

There is some evidence to support the suggestion that aromatic polyurethane coatings become embrittled and cracked after UV exposure; the following is copied from an academic paper; “It can be seen that after 1080 h of exposure, the binder is degraded and free particle clusters were found on the surface. Exposing the films to the UV light results in formation of deep cracks and holes and a non-uniform degradation in the nonstabilized films…..”

Binders for resin bound surfacing should be sufficiently elastic to withstand minor substrate movement and traffic loads; there is evidence of an increased risk of cracking of surfacings bound with resins which have low elasticity; especially when surfacings are applied to asphaltic bases, which are subject to flowing of bitumen binders at higher temperatures. When choosing a resin bound surfacing material, a specifier should weigh the superior properties of aliphatic resins when exposed to UV radiation against the reduced initial cost of aromatic polyurethanes and consider which offers better value for money to their client.

Resin Bound Aggregates

Natural aggregates are most commonly used but coloured glass and colour coated aggregate are also available. The designer should be aware that glass crushes more easily than most natural aggregates. In particular, glass has been known to suffer damage under high heeled shoe traffic. Quartz aggregate with UV stable colour coating can be sourced. However, coating loss can occur under regular medium to heavy foot traffic. The designer should consider restricting the use of coloured glass and colour coated aggregates to areas with little traffic.

Resin bound surfacing is suitable for foot traffic and light vehicle traffic up to 7.5 tonnes. Resin bound surfacing is not recommended for applications where heavy traffic or traffic by heavier vehicles is expected. Applications include car parks (excluding shopper’s car parks), driveways, podium decks and terraces, public squares, courtyards, footpaths and pool surrounds.